Our Services

PrecisionPro CNC & WaterJet

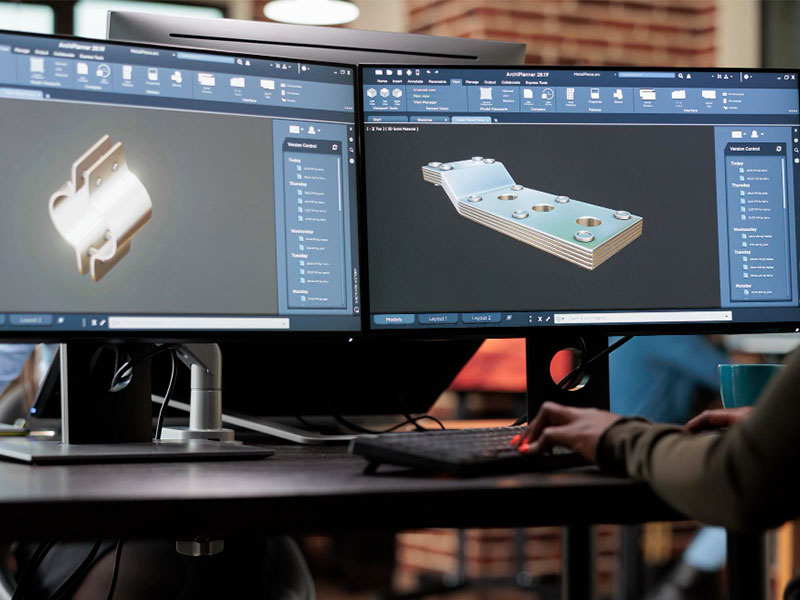

MANUFACTURING WITH CNC MACHINING

Generamos una gran ventaja al crear y producir con maquinaria

especializada CNC ya que con esto generamos mayor producción, ya que mediante estos optimizamos la calidad junto con la rapidez de las piezas produciendo un menor costo, ya que todo se programa en base a cada uno de los requerimientos que son personalizados. Con esto obtenemos mayor precisión y control de las dimenciones. Nosotros contamos con mas de 10 años de experiencia en el ramo metal- mecánico de control numérico, podemos fabricar cualquier tipo de pieza de maquinado cnc que nos envíes con el diseño o bien con una muestra podemos diseñarlo. Contamos con equipos de profesionales con experiencia en el sector del mecanizado y expertos en software de diseño y programación CNC y CAD/CAM.

WATERJET SERVICES

MANUFACTURING with pressurized and abrasive

We have great versatility as an advantage since it is our greatest asset, because the abrasive water jet cuts materials from 1.5 mm to more than 25 centimeters thick, in large or small runs, all this allows us to easily cut all varieties of materials. . Whatever the dimensions, shape or material, with our software there is no difficult job, to this we add that the stability we manage begins with our work area such as the table and continues with the flow of water that takes us to the strict tolerance that handles each of our pieces. We can see this in:

* Cold cutting processes.

* On lowered edges.

* In minimal incision cuts.

* In the production of its own facilities.

* Cutting any material.

* Simplifying processes.

We have environmental benefits since it is a cold cutting process that eliminates deformation due to slag and waste due to reductions, two undesirable effects that appear in plasma or laser processes. In addition, both the abrasive used in cutting and the water can be recycled.

WELDING MANUFACTURE & REPAIR

We have an advantage in terms of the types of welding we handle, since we handle brazing, which is one of the most versatile methods for joining materials, for several reasons:

* Welded joints are more resistant: In metals and steels not

ferrous, the tensile strength of a properly made joint; It generally exceeds that of already bonded metals. In stainless steels, a joint may develop with a tensile strength of 130,000 pounds per square inch.

* Welded joints are malleable, which can withstand strong shocks and vibrations, this generally makes them easier and faster to make, for this we have operators with the necessary skill.

* This easily generates assemblies that combine ferrous and non-ferrous metals, and metals with variable melting points. This welding is fundamentally a process that consists of a single operation.

* Welding allows us to compare the cost favorably with the

joints made with other metal joining methods.

3D SCANNING SERVICES

Thanks to the 3D scanning we use, we can collect the data

necessary to generate a three-dimensional image of an object, an environment or a body, with a projector that performs a 360º scan around each point. This gives us greater precision, since these can calculate millions of laser pulses per second, we can scan large objects or entire environments.

3D PRINT SERVICES

Thanks to the 3D scanning we use, we can collect the data

necessary to generate a three-dimensional image of an object, an environment or a body, with a projector that performs a 360º scan around each point. This gives us greater precision, since these can calculate millions of laser pulses per second, we can scan large objects or entire environments.

CNC PLASMA CUTTING SERVICES

We handle this cut that provides greater productivity because its

cutting speed is faster, which we can manage and calculate through each material, which generates greater cutting stability, which makes it versatile for cutting metals of thin and medium thicknesses, thanks to this we obtain greater precision and cleanliness in each cut.